Carbon-Negative Power

Using our teams extensive experience in aerospace, we’ve adapted the same technology that rocket engines use to leave the Earth to help save it instead.

Our technology gives the Earth’s natural CO2 removal processes a turbocharge. By collecting waste biomass from forests, farms, and landfills, and carefully converting it to a form we can store, we can permanently remove CO2 from the atmosphere while producing clean energy and water – a process known as Biomass Carbon Removal and Storage (BiCRS).

Next Generation Climate Engineering

We designed our system from a clean sheet with the goal of removing billions of tons of CO2 from the atmosphere every year. Leveraging rocket-inspired design concepts, advanced software and modern additive manufacturing, our carbon-negative system is the next generation of bioenergy. Our design achieves:

Permanent CO2 removal and storage

Flexible, scalable baseload power

Adaptable to any waste biomass source

Built and deployed in months, not years

The Carbon-Negative Process

It Starts With Nature

Plants are very good at removing CO2 from the atmosphere and, storing carbon in their bodies as biomass through photosynthesis. Unfortunately, when plants and trees drop leaves or die, that biomass becomes waste.

If left alone, that waste biomass will decompose and release the CO2 back into the atmosphere. Worse still, if waste biomass builds up in the forest it can cause wildfires and release billions of tons of CO2 all at once.

Waste Biomass

We begin our process with this waste biomass. We work with local farmers, state parks, and national forests to collect naturally occurring waste biomass before it decomposes or risks a forest fire.

Once this waste biomass is collected, it’s chipped and shredded to make it easier to transport to our power stations where we will process it and produce our carbon-negative power.

The Halcyon Power Station

Helping return the Earth to pre-human levels of atmospheric CO2.

Modular, scalable, and clean. Torrefied Biomass in, on-demand power and sequestered CO2 out.

Gasification

Once torrefied biomass reaches our power stations, it’s loaded into a gasifier. In the gasifier, torrefied biomass undergoes a series of chemical reactions that convert the solid biomass into a mix of gaseous hydrogen, carbon monoxide, carbon dioxide, and water, a mixture know as Syngas.

Any minerals or other solid impurities that can’t be converted fall out as ash and can be sold for use in agriculture or construction.

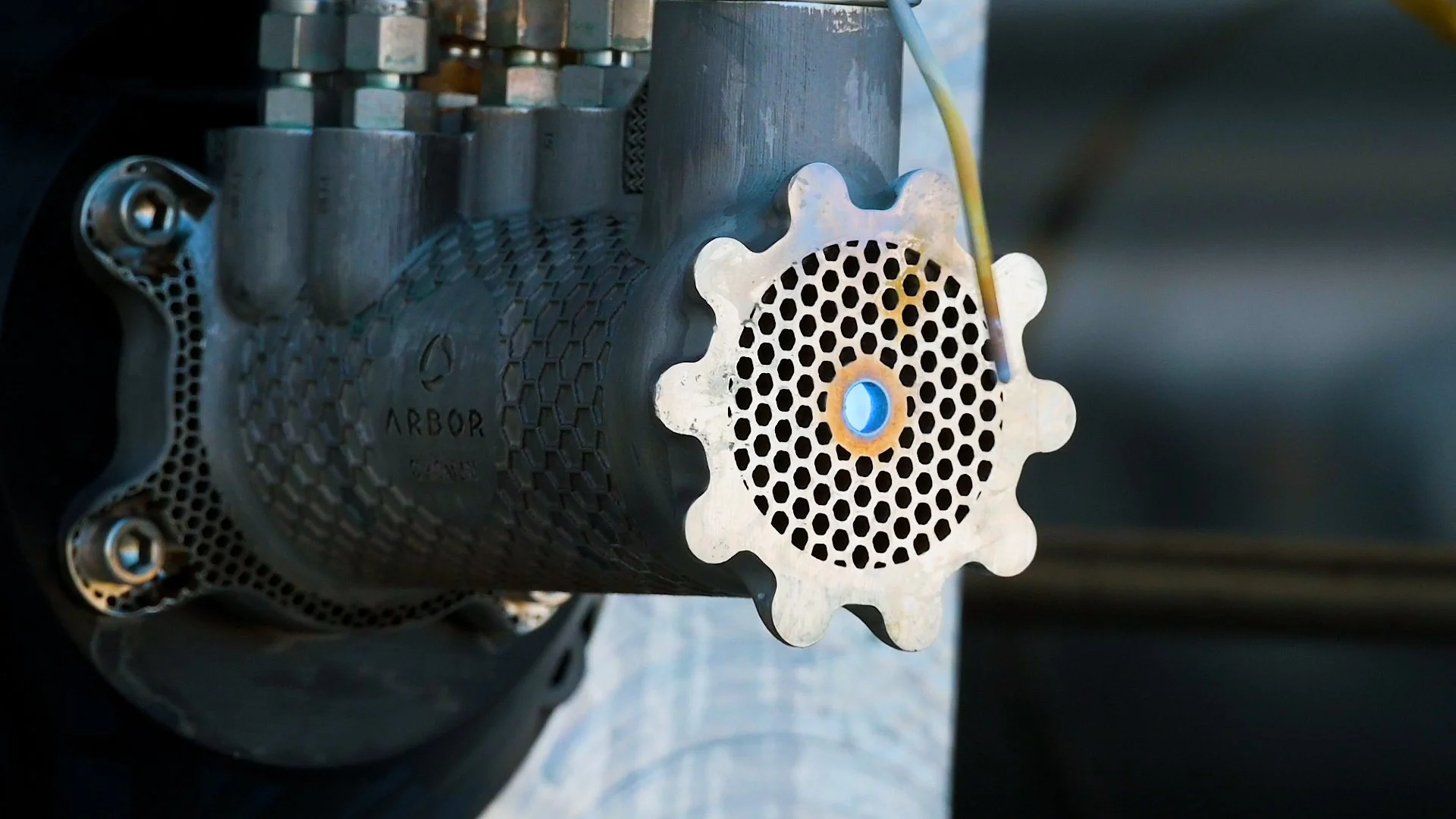

OxyCombustion

Syngas from the gasifier is fed into a combustor where it’s mixed with oxygen and burned in an Oxy-combustion reaction producing pure carbon dioxide, water, and releasing energy in the form of heat.

This high-temperature, high-pressure gas is fully contained so we can convert the heat into electricity, use the water, and store 100% of the CO2 we capture.

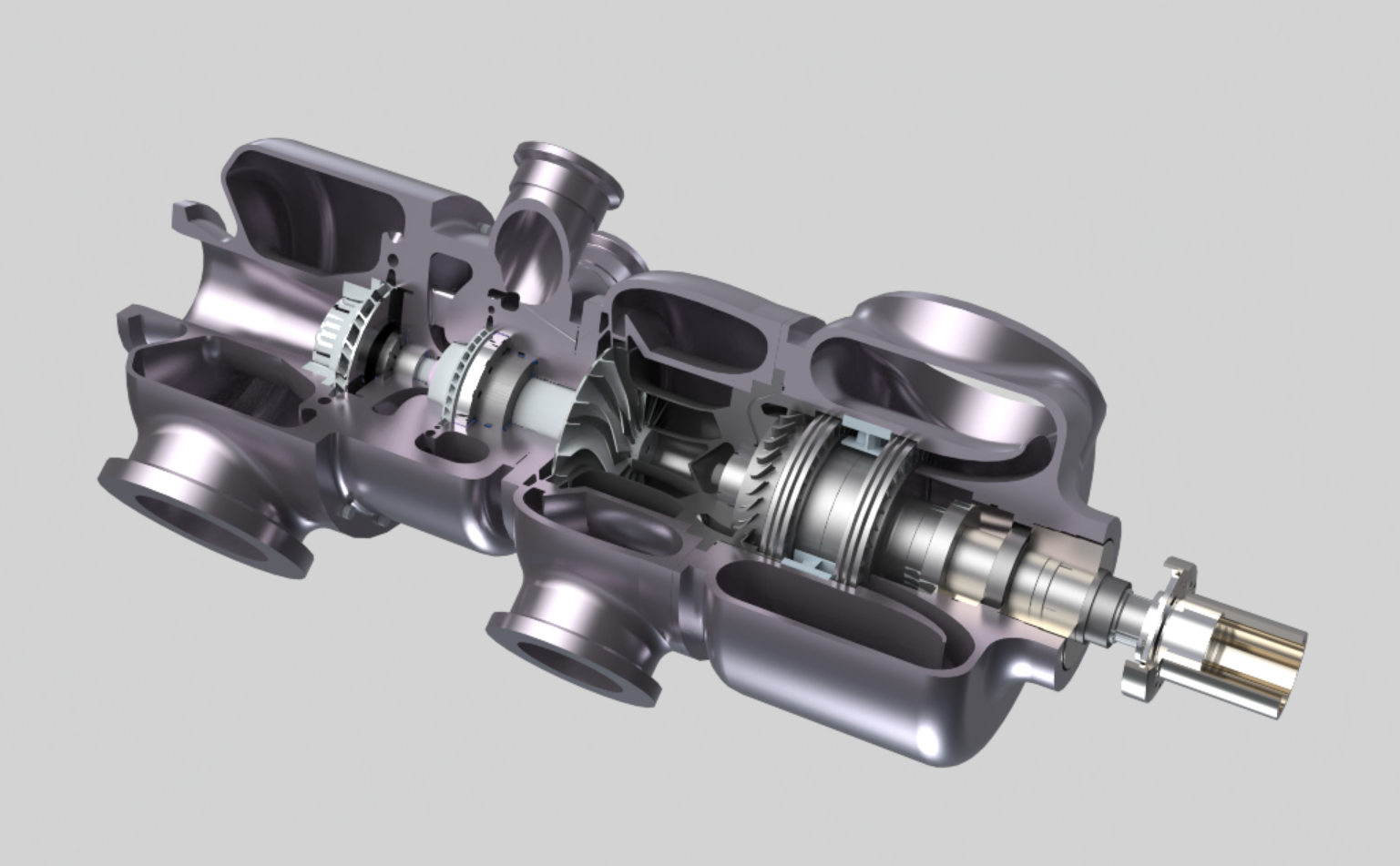

Turbomachinery

Coming out of the combustor the hot gases are expanded through a gas turbine which then spins a generator to produce electrical power we can sell to the grid as a flexible source of baseload electricity.

Once we’ve extracted all the energy that we can, the gasses are cooled and the vapor water is condensed out as liquid water.

Permanent CO2 storage

Finally, using excess exergy from the process, we compress 100% of the CO2 we’ve captured to a highly dense supercritical fluid and pump it into the ground.

Once it’s in the ground the CO2 will naturally react with minerals in the Earth forming limestone, permanently removing the captured CO2 from the atmosphere by putting it back into the Earth’s natural biogeochemical cycle.